In order to save our planet, we’ve got to get creative and rethink many of the materials that we use on a daily basis. Styrofoam is one ubiquitous material adding to our landfill problem. Some cities have banned its usage, while others are pledging to do.

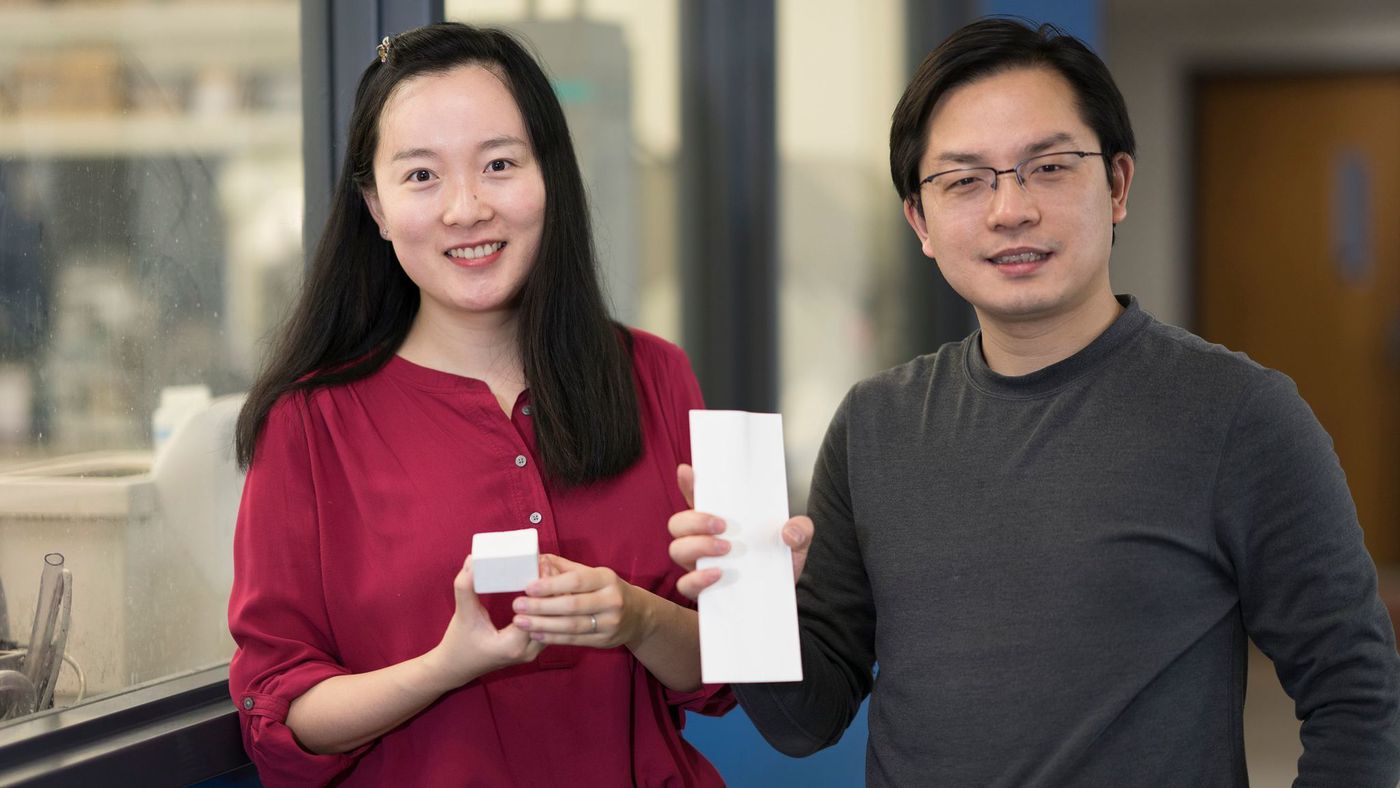

Tian Li, a post-doc student at the University of Maryland, has taken the no styrofoam pledge one step further by helping to develop a new material called nanowood. Working with researcher Liangbing Hu, nanowood acts like styrofoam and can be used in things from takeout containers to housing insulation.

What is Nanowood?

Nanowood is a material made from tiny wood fibers that that been stripped down into tiny fibers. It’s all natural, environmentally friendly—and best of all, inexpensive. “This [nanowood] can insulate better than most other current thermal insulators, including Styrofoam,” Li said. It’s a game-changer for energy-efficient building materials and makes sustainability not only possible, but would allow us to thrive.

Hu and the team have been working with the properties of nanocellulose, which is “nanometer-scale versions of cellulose.” This substance is the “tough carbohydrate” in cell walls of plants that allow trees to grow tall and strong. Cellulose fibers can take on amazing characteristics at small scales, including having a strength-to-weight ratio that’s eight times stronger than steel.

The UMD researchers had already developed super wood, a material that was made by removing the wood’s lingin, a complex polymer that’s like the glue that holds cellulose and hemicellulose together. Lingin also makes the wood brown and rigid. For nanowood, Hu and his colleagues removed all of the lingin and most of the hemicellulose. The result altered the super wood into a white material that reflected incoming light, making it great for blocking heat. But, it also has fibers bundled in parallel strands that allow heat to travel up and down the fibers easily, but not across them.

The Future with Nanowood

“To the best of our knowledge, the strength of our nanowood represents the highest value among available super insulating materials,” the study authors wrote in Science Advances journal. It outperforms commercial thermal insulation materials. “When exposed to the solar spectrum, the silica aerogel absorbs ~20% and transmits ~60% of the radiative heat,” the study authors wrote. “In comparison, ~95% of the radiative energy was reflected, whereas only ~2% was found absorbed by the nanowood.” The material was even awarded “best insulator” by Guinness World Record.

Sometimes, the answer to solving environmental energy problems isn’t creating a brand new material—it’s reinventing something we already have. Nanowood can be made into blocks or as a thin, flexible form. When it is less than 1 millimeter thick, a nanowood slice can be rolled and folded. This means it’s capable of going into pipelines in chemical factories and power plants.

The future uses of nanowood seem endless—imagine it in cars, buildings, heat-sensitive electronics, and in space. With such theoretical demand, how do they keep it sustainable? Harvest fast-growing trees like balsa to ensure that slower-growing ones aren’t affected.